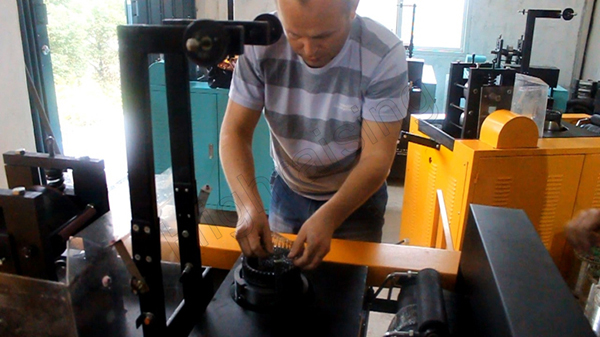

W2 High-yield Full Automatic Scourer Manufacturing Machine

Basic Data:

1.Model: W2

2.Color:Blue/Grey/Yellow

3.Voltage: 380V and 220V(380V, 3 phase, 4 lines.is the first choice)

4.Power (kw):1.5KW

5.Setting wire: 2 wires and 2 scourer come out

6.Net Weight :400kgs

7.Gross Weight: 460KG

8.Installed Machine Size: 180(L)cm x 105(W)cm x 150(H)cm

9.Export wooden case size and weight: 180(L)cm x 110(W)cm x 160(H)cm, 60kgs

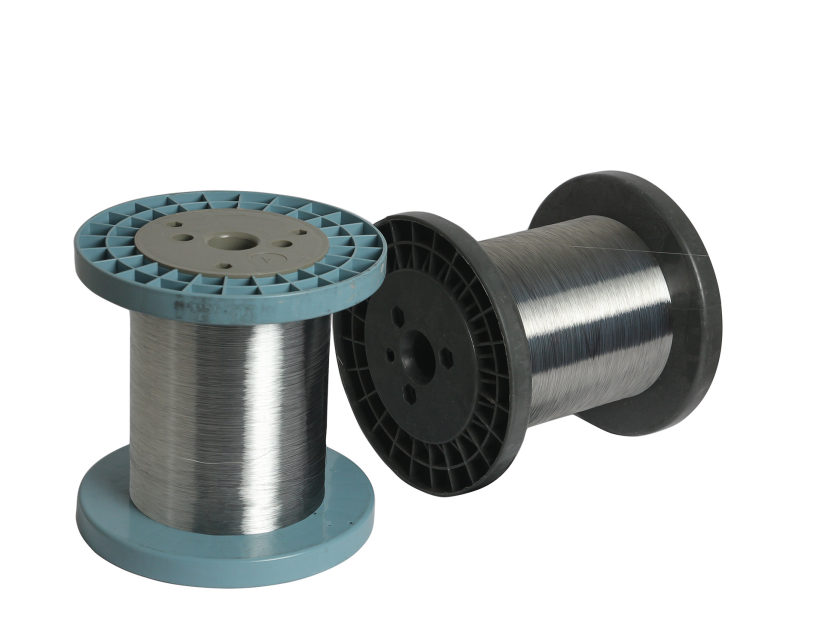

10.Materials feeding: Diameter 0.20mm Stainless Steel Wire(exclude 304), Galvanized Steel Wire Wire and plastic wire

Advantages of W2 over other suppliers:

1.with full-automatic operation system digital control Counter

2.available for two kinds of scourer on the left side ,the common scourer and spire scourer

3.highest output in this field, can be as many as 6KG/Hour

4.high accuracy for the weight of scourer from 6g - 60g adjustable

5.Size,weight,lose or tight can be customized and set through the digital controller

6.patent technology-Automatic stop device which can save raw material and human cost so that one experienced worker can take care of 6 -W2 machines

7.Motor accelerating: from 0 to1600r/m within 0-5 seconds,stable and constant without broken wires

Order terms & Service of W2:

1.we have been in this field for 21 years ,we can supply scourer making machine,package,raw material,grinder,export service,technology treatment,marketing treatment and after-sale service.

2.Minimum Order Quantity: TWO SETS

3.payment term: 30% deposit and arrange the 70% balance before delivery

4.Delivery time:15 working days after paid or deposit.

Introduction to Equipment Performance of W2:

The CNC Full-automatic high-yield W2 scourer making machine,

this scourers making machine, is operated by single operator in the processing of wire material feeding, forging pressing,planing,stretching, and Computerized Numerical Controlling scourer ball separation, etc. It has strong stability and fine compatibility.

The feeds of materials suit for iron wire,galvanized wire,stainless steel wire, brass wire, etc, which can make your different scourer scrubbers at one time on one W2 machine.

In the aspect of intellectualized-designing, the size of the separated scourer ball adopts full-automatic management of Computerized Numerical Controlling, which thoroughly eliminates the primitive way of counting by time and reminding the operator of separating scourer balls by light glittering,the weight accuracy of each scourer ball is controlled in 0 error. The scourer balls separate automatically after formed. Appearance of the scourer ball can be adjusted according to the different consumption levels.

W2 scourer scrubber making machine is collocated with the governor of 2.2kw (the common machine collocated with governor within the 1.5kw is unable to finish high-speed operation of multi-wire into single scourer ball.If the machine collocated with governor of 2.2kw is unable to finish the six-wire by single person operation,it will be power-waste).

Whiling W2 scourer making machine is under the speed of governor running from 0/s up to 1600/s circles is less than 5 seconds! This is the best way to examine whether the scourer making machine will break and jam the wires,the output level,and whether its design is reasonable,too. The performance and output of this equipment is leading in the field of the same machinery type. It dares to compare with any metallic scourer making machines!

FAQ:

1. What kind of power supply will your machine use?

2.

1. Standard Industrial AC 380V, frequency 50Hz, three-phrase four-lines is more stable

2. AC 220V 50Hz(60Hz) is available to our machine since year 2006, custom-made only but not recommend.

3. How's the power consumption of each model per hour?

A6(Stopped): 1.5KW/Hr

A6 for Galvanized iron stainless steel scrubber: 2.2KW/Hr

W1 for wire mesh scourers knitting: 0.75KW/Hr

W2 for knitting mesh wire scrubbers: 1.5KW/Hr

4. Are there other equipment & accessories required and their dimensions?

Does not need other equipment & accessories usually. We offer extra and optional accessories for maintenance preparing:

1. Rubber wheel (6pcs/set) Diameter:55mm Thickness:45mm

2. Compression roller(1pair/set) Diameter:150mm x 80mm

3. It's better to own a round grinding machine for rollers grinding.

4. Can you provide spare parts for 3 years for each model? How's the machine's abrasion and its expenses?

Does not need other equipment & accessories for ordinary production. Our specific compression rollers, rubber wheels and other spare parts will be available for optional extra. Machine abrasion plus material waste, we calculated that the loss is about USD12.65/ton. (Calculated in year 2006)

See next question for more about abrasion.

5. How long should we have to grind the compression roller? and how long is its life?

We don't say how long, we say how many the products output were made.

For galvanized steel and iron wire material, you should to grind the roller per 1500kgs(approx) pot scourers produced.

For Stainless Steel Wire material, the grinding time is per 350kgs to 400kgs pot scourers produced.

The life is after about 35 tons pot scourers scrubbers produced. Usually the compression rollers replacement would be at after three years.

When you make your daily output more than 110kgs, please count maintenance time and stop running time, the compression rollers should be replaced after about two years.

6. What kinds of pot-scourer can your machine make?

Model A6 - for kitchen Stainless Steel scourers, Galvanized Iron Wire scourers, and other spiral scourers scrubbers.

Model A6 - for Galvanized iron scrubbers, stainless steel scrubbers, and other spiral kitchen pot scourers.

Model W1 - for wire mesh scrubbers, copper scourers, brass scourers, s.s scourers, and galvanized scrubbers.

Model W2 - for mesh wire knitted scourers, copper wire scrubbers, brass wire scrubbers, stainless steel scrubbers, and Galvanized Iron Wire scourers

7. What is the scrap (production waste) volume when we start to manufacture pot scourers?

It is according to the materials you bought, the quality of machine,and operator's skills. Our machine in good materials with the specialized worker, the waste is about 0.3% to 0.6%. unskilled operator will make waste about 1%.

8. Can machines be used in continuous three 8-hour shifts?

24 hours for a once time maintenance will be good to the machine. We didn't find any troubles after run 10 days continuously.

9. What's the output production of each model in Kg. per 8-hour shift?

A6: 80kgs/8hours,

A6: 100kgs-120kgs/8hours

W1: 16kgs-24kgs/8hours for for wire mesh metallic (copper, brass, stainless steel, galvanized iron) scourers scrubbers. Brass and copper soft metal material wires will have higher output.

W2: 32kgs-48kgs/8hours for mesh wire knitting metallic (copper, brass, stainless steel, galvanized iron) scourers scrubbers. Soft metal material like brass wire and copper wire will have higher output.

10. Which type of coolant is being used ? please give us material name.

Does not need any coolant. Water or oil(white color) will be helpful to get final scourer scrubber products more shining, but not necessary to our machine. Our machine could work in pure dry environment, you could pack it immediately don't need to wait water dried.

11. Is shining of scourer depended upon row material or coolant or any other operations of machine ?

Shining color has not too much difference from different materials, however putting a little water or oil will make final scourers scrubbers more brightness.

12. Are the sizes of the produced scourers (in Grs.) adjustable?

It is the Computerized Numerical Controlled machine, you can adjust your scourer product at any weight you like. such as, 15g, 15.g, 16g, 21.50g, 50g, 50.9g. 60.1g, etc. The weight error is about +/- 0.3g

13. Are there any man power requirement in scourer production?

Only material feeding, final scourers picking up and packing.

14. Is there a necessary to train workers ?

Does not need special skills. Skilled operators will increase scourer output and extend the machine's life. Recommend to be trained in our factory in China, we have special training programs for free to all of our users.

15. How long period does it take you train a skilled operator?

Three to six months. A new operator will make about 1% waste. After 3 - 6 months, most operators will be very skilled, the material waste will be about 0.3% -0.6%.

16. How many machines can be operated by one skilled operator?

One operator takes care of 4-5 machines.

17. Is the raw material of S/S wire available in China? If yes, would you quote the best price for brass, galvanized steel, iron wires of best grade?

Raw material of S S wire is available in China.

We introduce the material wire factories to meet your pot-scourer production.

For good quality, diameter 0.125mm-0.13mm stainless steel wire raw material, the price is about USD2150 FOB Shanghai/MT(in year Aug. 2010), the material price is fluctuating in market.

18. Do you have or can you find the required packing machine for us?

Yes,we have friend who can product different kinds of packing machines

19. What's the total required space for each set of machine and related equipment & accessories?

150(L)cm x 110(W)cm x 160(H)cm

Suit for A6, -A6, -W1, -W2

20. How many sets of each model will fit in a 20' FCL?

It will fit to 8 sets in a 20'FCL.

The size of 20' FCL is: 5.899M(L) X W2.352M(W) X 2.386M(H)

The machine size include packing plus common spare parts is: 150(L)cm x 110(W)cm x 160(H)cm

21. What is the packing method of your scourer making machine?

No packing for domestic market in China.

Wooden case for export packing to all of our pot scourer making machines.

22. Can you help us to set up the machine? is this trouble to install?

Does not need special skills to install, it's very easy, just put it in your workshop, connect to electricity socket, feed material. That's all, gets start to make your scourers scrubbers.

We also offer door to door service for free to help our domestic customers to set up machine in China when more than 3 sets scourer making machines were bought in one order.

We do the same service but the international business travel expenses will be requested.

23. Can you send us 1~2 sample(s) of scourers made by your machines using different materials? or Can you offer some pictures of physical scourers which were made by your scourer making machine machine?

Please let us know your collect account No. of your courier company, detailed delivery address, company name and telephone number. We will send you the finished scourer scrubbers samples for free, which are made by our scourer specific manufacturing machine.

If you don't have a collect account number of your courier company, the shipping freight will be requested. This expenses will be 100% refunded to you after you placed real order.

25. Do you guarantee your machines? If yes, for how long?

Our scourer scrubber making machine is very stable, won't have troubles in common use. We have 12 months guarantee for domestic buyers in China. You will have some free spare parts for one year use along with your order.

27. Does your factory has ISO certificate? Under what standard are your machines made and do you have a quality control section at your factory?

ISO costs high, we give our customer more competitive price.

There's no international or national standard for this scourer machine, we have very strict quality control section ourselves. We are leading and specialized manufacture in China for the scourer scrubber manufacturing equipment. The quality is very good, you could inspect at our factory to confirm.

28. Is it possible we visit your factory? If yes, how to reach you?

You are our valuable guest, you are very welcome to visit our factory, you will get more confidence after you inspected our machine in person.

Please ask your local travel agent to get into Wuhan China, we pick you up at Wuhan International Airport or Wuhan Train Station. We drive you to our factory, and help you to book the hotel in Wuhan as well.

29. Can you send "Invitation Letter" for us to the P.R of China Embassy in my country for visiting you and your factory?

No at this moment. Our government controls such invitation. Ask your local travel agent for help.

30. How long will one set machine order take?

Usually in about 10-15 working days after your deposit was verified. To be on the safe side, you have to consider to place your order as early as possible, our marvelous scourer scrubber making machine is growing more and more popular in world market, first come first served.

31. Do you accept payment by L/C? or other payment methods?

Before shipping, your money in our company's account is perfectly secure and reliable as like your own bank-safe-deposit-box in China. Keep safety-first to a small business, please don't pay to a private accounts. We have three methods for your Payment as below:

1. 100% pay at factory, pick the scourer making machine up immediately. You arrange shipping by yourself. We like this way!

2. 30% deposit T/T in advance, 70% effected by T/T before loading, and after you inspected, or we send you shipping photos if are not able to come.